Should you outsource your eCommerce fulfilment?

As an online retailer, your business will inevitably hit stumbling blocks that hinder growth, so it’s important to identify them as early as possible. Whether it’s your shipping costs, technical infrastructure, warehousing and storage, product sourcing, sales and/or marketing, there are always economies of scale to be had, and efficiencies to be gained. In this article we’ll focus on the order fulfilment element of your business, to help you make an educated and informed decision.

What is eCommerce fulfilment?

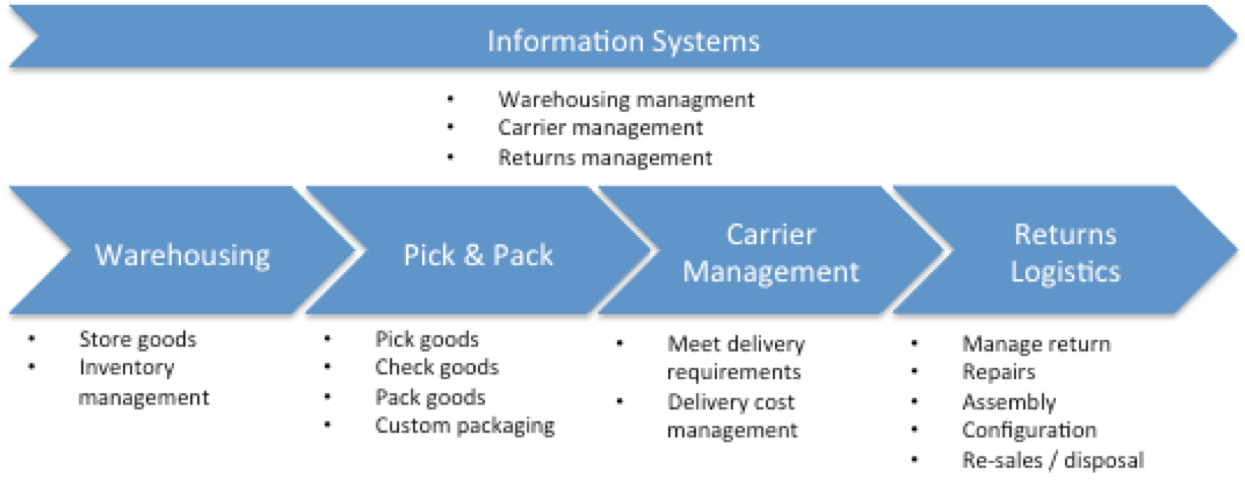

eCommerce fulfilment is the process of entrusting a third-party specialist to receive your finished products from your suppliers, store them, rework, and process your orders, in real-time. Also offering shipping solutions, returns and in some instances, outsourced customer service, these warehousing companies specialise in a plethora of market sectors, from homewares, to luxury goods, to pet supplies, health and wellness, beauty, sports nutrition, subscription boxes and more. More recently, fulfilment houses are innovating to offer a broader range of features, such as inventory analysis:

Demand for warehousing shows no abatement; the global eCommerce fulfilment services market size was valued at USD $85 billion in 2021. It is expected to reach USD $208 billion by 2030, with a predicted compound annual growth rate of 10.4% for this period. Demand is so strong, in fact, that retailers are offering their own on-demand warehousing solutions to other retailers, contributing to the sharing economy.

How a 3PL can benefit your business

For more established SMEs and mid-market retailers, the most popular solution is to work with a dedicated eCommerce order fulfilment company, that aligns in terms of technology ecosystem, and clients’ markets.

Because fulfilment outsourcing companies work with tens, hundreds, and in some instances thousands of retailers, brands, wholesalers and manufacturers, merchants benefit from 3PLs’ group buying power, giving them access to preferential shipping rates, accelerated order processing, increased order accuracy and the expertise of a fulfilment house, with regards to elements like packaging and labelling efficiency.

Many retailers miss out on sales, due to early courier collection cut-off times, and some fulfilment providers, such as Zendbox, have can help with this. This 3PL has enabled their client win more international customers, boost profits, and outsmart the competition, with an ultra-late 9pm order cut-off time:

“We’ve saved a lot of time worrying about when the courier is going to come. Sometimes the courier turns up late. With Zendbox, we’ve got complete trust that our products are going to be sent out on time. The majority of our orders will come in in the evening. Now we’ve got a later cut-off time with Zendbox, we’ve noticed less abandoned carts, we noticed people were shopping with us simply because of the later cut-off time.”

The potential disadvantages of outsourcing fulfilment

The first disadvantage of outsourcing third party logistics, is that not every business can access it. Minimum order volumes typically start from around 10 per day, but some fulfilment companies insist on as many as 300. When outsourcing your pick, pack and despatch, you will have less direct control over your business operations.

When transitioning to an outsourced business model, there will also be an adaptation period, which can, in some instances, impact customer experience and delivery performance, for a period of time. A more involved fulfilment house may also get involved with reworking and customisation, increasing the chance of adaptation problems.

The stages of order fulfilment

Order fulfilment begins with being set up as a client. At this stage, the 3PL will assess your technical infrastructure and sales channels, to ensure smooth integration with your systems. The next stage is to agree on storage, picking and packing rates, along with courier pricing.

Once setup is complete, you will instruct your suppliers to now ship your finished goods, in bulk, to the 3PL, as an ongoing activity. On receipt of your goods, the goods in team will allocate storage locations, adhering to specific picking areas. As orders flow in, the pick and pack team will be notified, and collect the correct product, ready to add a shipping label.

Following collection by the courier providers, your customers will receive tracking details, and depending on the carrier selected, your customers will have a range of different in-flight delivery options. Forward-thinking 3PLs will use proactive technology to predict WISMOs (where is my order? incidents), to maximise the chance of first-time delivery success, and minimise inbound customer service queries. After delivery, fulfilment firms can help with returns, and in some instances, customer service queries.

The different types of pick and pack warehouse

3PLs also differ in terms of level of involvement, how deep they reach into your supply chain, and how helpful they can be with optimising your stock levels, to avoid missing out on sales.

Finding the right fulfilment house

With soft skills more in demand than ever, 3PL clients place a lot of importance in the quality of their in-person relationship with the fulfilment house. This means dedicated account management, technical support and a friendly, proactive workforce are key. Will they continually review your shipping rates, and offer price transparency against their competitors? Will they reinvest their gross profit into technological innovations?

Upon meeting your 3PL candidates, follow your gut, and question whether you can entrust the most delicate element of your business operations with this company. It is also key to negotiate your contract and establish SLAs (service level agreements), in terms of variables like order picking accuracy, WISMOs (‘Where is my order?’ queries), order processing speed, and on-time delivery performance.

Taking a more black-and-white perspective, pricing is critical, but not at the detriment of customer experience. Skimping on costs can lead to gaps in service quality, so finding a balance between cost efficiency, and finding a 3PL that truly has your back, and doesn’t view you as a commodity, is paramount.

77% of negative reviews are directly related to issues shoppers experience after clicking ‘buy’. There are many touchpoints after the buy button that can go wrong, from poor customer communication, to items not being delivered on time or at all. Any of these operational failures can lead to an unsatisfactory shopping experience that results in poor feedback. The same study found that 88% of online shoppers consider a retailer’s feedback before purchasing, therefore getting shipping and fulfilment right can impact repeat custom (and customer lifetime value), but also customer acquisition. Continually reviewing your fulfilment provider is meeting agreed SLA performance, and is competitive from a pricing standpoint, will help you minimise your overheads over time.

To outsource, or not to outsource?

In this article we have covered the various elements of eCommerce fulfilment, and things to consider when looking to outsource it. Investing in your own fulfilment operations is capital-intensive, in terms of hiring staff, buying or renting your own warehouse, kitting it out with pallet racking, barcode technology, forklifts, insurance, and setting up your own relationships with courier partners. Find the right 3PL, and you can instead invest in maximising customer acquisition and retention, while the fulfilment specialist takes care of enhancing your post-checkout customer experience.